Janome sewing machine repair in boulder

A profession for some and a wonderful pastime for others. That’s what sewing is in a nutshell. Regardless, a broken sewing machine will undoubtedly drive a wedge between you and your sewing projects. Vacuums R Us & Sewing to in Boulder can help make sure that it doesn’t happen often by performing regular maintenance and service on your sewing machine.

Vacuums R Us & Sewing Too – Boulder Store

3005 28th St

Boulder, CO 80301

Corner of 28th & Valmont in front of Rayback Collective

(303) 449-8913

Working on a sewing machine that needs repair or a tune-up will lead to more troubles and eventually cost you to replace the entire unit. Further, it will also never let you create the final showpiece you have in mind. One effective way of getting all your problems fixed with little hassle is by placing your precious sewing machine in the hands of an experienced and reputable sewing machine repair company.

So, if you are looking for sewing machine repair in Boulder, we at Vacuums R Us & Sewing Too–Boulder Store would be more than happy to offer our services to you. We are armed with a team of factory-authorized technicians that take on any type of repair, especially Janome sewing machine repair at our store in Boulder.

Authorized to service some of the biggest brands of sewing machines available such as Singer, Viking Husqvarna, Elna, and Elnitta, we also offer a 90-day warranty for all products serviced at the Boulder store. But truth be told, you’d never have to use it when our technicians are done with your machine. Further, there will be no charge

$89.99 Mechanical Sewing machine tune up!

* Parts extra. Restrictions apply. $119.99 for computerized machines.

Choose a method to receive this coupon and more!

By clicking “Sign up” you agree to allow us to send this coupon via the email or phone number you provide followed by a maximum of three text messages/month and/or 15 emails/year with related coupons, offers, and sales. Unsubscribe at any time by texting STOP or clicking unsubscribe. Message and data rates may apply. We do not share our customer’s information with any other companies.

SEWING MACHINE SERVICE INCLUDES:

TENSION ADJUSTMENT, NEEDLE BALANCE, CLEANING, OIL, GREASE

SEWING MACHINE TYPE & SERVICE PRICE

MECHANICAL MACHINES $99.99

COMPUTERIZED MACHINES $149.99

SINGLE NEEDLE EMBROIDERY MACHINES $179.99

MULTI-NEEDLE EMBROIDERY MACHINES $279.99

LONG ARM MACHINES $249.99

SERGER/OVERLOCK MACHINES $149.99

FRONT OF HOUSE DIAGNOSTIC FREE

BENCH DIAGNOSTIC $45

A Quick Look Into How A Janome Sewing Machine Works

Although we at Vacuums R Us & Sewing Too–Boulder Store service all brands of sewing machines out there, this article will primarily focus on our Janome sewing machine repair process. First, let’s take a quick look at how a common sewing machine works and before diving into the repair procedure.

If you’ve ever stitched by hand, you know the needle moves in and out of the fabric in a motion that’s quite different from that of a sewing machine. It is also a motion that’s quite hard for a machine to replicate without damaging the fabric. So how could a sewing machine create the beautiful stitches you see when sewing?

A sewing machine creates its stitches by using a system called the bobbin mechanism. It uses two threads to create a stitch. One of these threads, called the top thread, is fastened onto the needle while the bobbin feeds the other thread called the bottom thread onto the fabric. When the needle punctures a fabric, a hook (known as the shuttle hook) in the bobbin mechanism grabs hold of the top thread. As the needle lifts, the top thread, that’s gripped by the hook makes a loop. This loop is placed across the bottom thread that runs along the fabric to create a stitch.

Therefore, in short, your sewing machine creates stitches by looping the top thread around the bottom thread. This process repeats itself every time the needle punctures the fabric.

What Can Go Wrong?

Although the bobbin system is the key feature of a sewing machine, there are so many other inbuilt mechanisms that help create that perfect stitch you are looking for. A minor setback on any of them can result in an unsatisfactory outcome. This makes it quite hard to track down the issue without a proper understanding of the matter.

A problem that’s quite common in a Janome sewing machine is the timing of the stitches. The time that it takes the needle to puncture the fabric and the shuttle hook to grab onto the top thread needs to be perfect because a delay here will cause stitches to skip. It will also delay the time taken by the shuttle hook to reset.

Our technicians at the Boulder sewing machine repair store take great care when dealing with timing because a mistake here will render your Janome sewing machine useless. The fabric feeding system, also known as the feed dogs, helps in the timing process as well. It feeds the fabric so that you get equally spaced stitches. Any issues with the feed dogs will cause you problems like overlapping stitches.

The mechanisms that provide tension to the threads are another important part of your sewing machine. The overall tension in the thread distribution of the machine needs to be just right. Too tight and the thread might snap, too loose and you’ve got a bunch of detached stitches.

The In-House Sewing Machine Repair Process

We at Vacuums R Us & Sewing Too–Boulder Store pay close attention to all these issues and more. Because of the countless sewing units we’ve repaired over the years, our technicians are well versed with almost all sewing machine issues out there. So, we will most likely have a solution for your machine’s problems as well. Apart from the machine itself, our techs will only require the common presser foot, foot control, power cable, bobbin holder, and the bobbin from you for the tune-up.

Power Check

Once our technicians get their hands on your Janome sewing machine, they check for any power-related issues that the machine may have. They check for any problems in starting the sewing machine, the panel lights, and if the machine comes to any sudden halts during operation. They also go through the power cables, foot control, and other powering devices that might be part of your sewing machine.

A Trial Run & Burr Check

Once the sewing machine is powered up, they will test its operation. They will create a series of different stitches using the machine and note down any complications they run into. This trial allows them to recognize any problems and also gives them an initial state to compare with the final serviced sewing machine.

Along with the trial run our techs check the machine for burrs which cause broken threads and uneven stitches.

Thread Distribution & Bobbin speed

As mentioned before, both the top thread and the bottom thread go through various parts of a sewing machine to produce a stitch. So, if the thread isn’t distributed across each mechanism with the right tension, the machine will not perform at its best. This is a crucial step in our sewing machine repair process and we pay a great deal of attention to it.

First, our techs evaluate the stress on the top thread once it’s fed through the machine. They make sure that it passes through every mechanism it has to. After confirming that there’s no damage to the stress discs, they move on to check the bobbin winder. The stress on the bottom thread is then evaluated and corrected if it shows any issues.

Next, our technicians check if the bobbin speed is up to standard. Bad bobbin speeds lead to timing issues in a sewing machine. So, if our techs find a problem with it, they will make the adjustments to get it back to an optimum spinning speed.

The Feeding Mechanism

Almost all Janome sewing machines have a mechanism that feeds the fabric into the machine. Generally called Feed dogs, they contain a pair of teeth that move in unison to get the fabric under the needle. A problem in the feeding mechanism will cause overlapping and uneven stitches.

Our technicians will inspect the teeth for any damages and also test their forward and reverse movements. Other additional features such as elevating and lowering mechanisms of feed dogs will also be checked.

Under The Cover

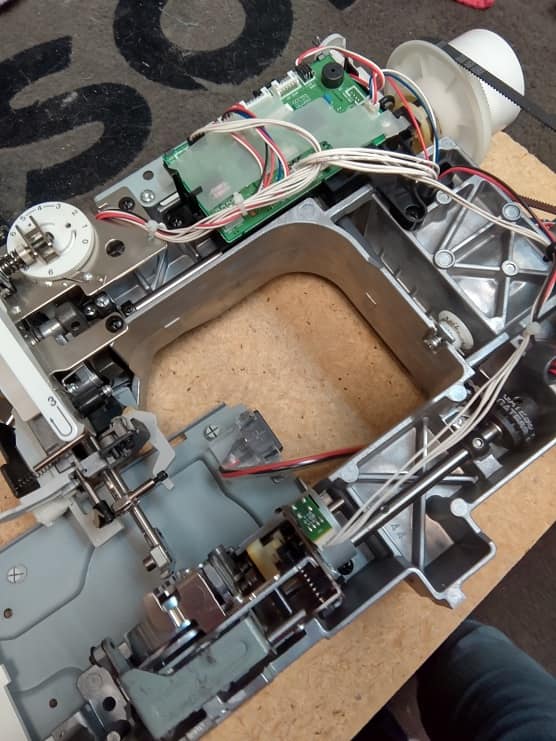

After our techs finish working on the external parts of the machine, it’s time to strip the machine of its covers.

Once the covers are off, our technicians clean the inner chassis to get rid of any dust and dirt they might find. They use various specialized tools to make sure that they reach every part of the machine during the clean-up. Old oil, grease, and other lubricant are removed and replaced so that the parts function more smoothly.

After this extensive cleaning session, our techs get to work on the sewing machine’s timing. They make sure that the eye of the needle goes into the bobbin location and that the shuttle hook grabs the top thread at the correct time.

They will also install a brand new needle and check if the needle elevation is up to standard. And if it’s not, they’d fix it!

Updates

It’s already quite hard to keep track of the updates the digital devices in a household need. And adding an electronic sewing machine into the mix will not help. But we at Vacuums R Us & Sewing Too–Boulder Store will make sure that your sewing machine has the latest update installed when handing it back to you.

A Thorough Wipe

Once the covers are back on and every part is where it should be, we give your sewing machine a final wipe. We use cleaners that are “sewing machine friendly” so that there’s no damage to the body.

Will It Pass?

Finally, our certified professionals put your newly serviced and gleaming sewing machine through a final test. The test comprises two parts.

The first part is a speed test in which the machine is run at maximum sewing speed. This will confirm that the motors work fine and run efficiently for an optimum sewing experience.

The second part will be a stitch test in which various stitches such as straight stitches and zig zag stitches are created by the machine. But what if your Janome sewing machine fails any of these tests? Well, if it does, it’s heading right back to our workshop. However, we have yet to see one that fails.

Frankly, it’s quite hard to stuff all the things our technicians at Vacuums R Us & Sewing Too-Boulder Store do into one article. But hopefully, this read gives you an idea of what your sewing machine goes through when it reaches our sewing machine repair service in Boulder. Hand us your sputtering sewing machine and we will make sure that it works just as well as a new one!