Central Vacuum Repairs and Installation

A central vacuum needs regular maintenance.

It’s recommended that you get it serviced every 6 to 12 months, depending on how often you use it. Apart from regular maintenance, you should also get the central vacuum system examined if you suspect any troubles with it. Most unresolved issues lead to more severe problems if they are not fixed ASAP. And when you get it fixed or maintained, make sure that you employ a trusted and experienced central vacuum service center.

CENTRAL VACUUM SERVICE RATES

Onsite call includes first hour labor

$149.99* within 10 miles of store

$224.99* 11-50 miles from store

$79.99* per additional hour

(*PLUS PARTS)

Contact us to schedule a house call (303) 455-3096

Shop Local!

Free express shipping in Colorado

Established 2003

Local Colorado Company

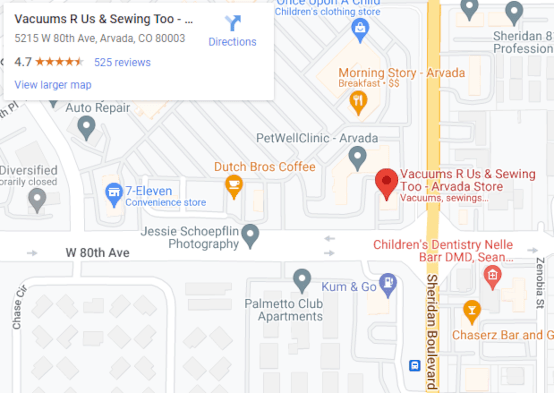

Arvada

Vacuums R Us & Sewing Too – Arvada Store

5215 W. 80th Ave.

Arvada, CO 80003

(303) 455-3096

Hours

M-F: 9-7

Saturday: 9-5

Sunday: 10-4

Holidays: 10-4

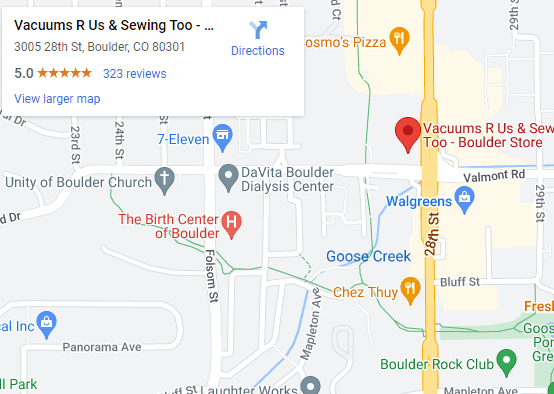

Boulder

Vacuums R Us & Sewing Too – Boulder Store

3005 28th St.

Boulder, CO 80301

(303) 449-8913

Hours

M-F: 9-6

Saturday: 9-5

Sunday: Closed

Holidays: Closed

Fort Collins

Vacuums R Us & Sewing Too – Fort Collins Store

501 Riverside Ave.

Fort Collins, CO 80524

(970) 223-7327

Hours

M-F: 9-6

Saturday: 9-5

Sunday:Closed

Holidays: Closed

Central Vacuum Unit Installation

Along with the inlet installation, our techs will also start fixing the central vacuum unit. Usually, central vacuum units are installed in the lowest room of an establishment. This is because it saves energy to vacuum towards a lower point as there’s no resistance from gravity. So it’s common to install the central unit in a basement.

The position, however, depends on how the wires and pipes come into the room. The incoming pipes are joined using a “Sweep T” or T-joint before connecting to the suction inlet of the unit. Most households only require one or two suction inlets of the vacuum unit.

While fitting the central unit, our specialists will also install a separate exhaust system if required. These exhaust systems are directed outdoors.

Wiring, Pipes, And Ducts

Using the markers placed before as indicators, our experts will start running the pipes, wires, and ducts throughout the household. This is probably the most painstaking part of the process. It requires a couple of skilled hands and a cool head because one wrong turn within the walls and you are going to end up against a dead end.

Our techs use a variety of tools and techniques such as stud finders to get the installation right. They also try their best to remove any burrs they find, especially when drawing the wires. Burrs and sharp edges lead to split wires which will affect the performance of the system. Once everything is fixed in place, we power up the system and carry out a top-to-bottom inspection to avoid any oversights.