Sewing Machine Repair in Boulder Colorado at Vacuums R Us & Sewing Too – Boulder Store

The things you create with your sewing machine are an expression of your own so when your machine requires repair, service or maintenance make no concessions. Service on most models and brands of sewing machines are performed in store at our Boulder Colorado location by factory certified technicians employed by Vacuums R Us & Sewing Too – Boulder Store! All service done in our Boulder location carries Vacuums R Us & Sewing Too’s rock solid 90 day warranty. Deposits are not required at time of service check in and if we find that a machine is non repairable due to discontinued parts or other complications there is no charge!

Vacuums R Us & Sewing Too – Boulder Store

3005 28th St

Boulder, CO 80301

Corner of 28th & Valmont in front of Rayback Collective

(303) 449-8913

SEWING MACHINE SERVICE INCLUDES:

TENSION ADJUSTMENT, NEEDLE BALANCE, CLEANING, OIL, GREASE

SEWING MACHINE TYPE & SERVICE PRICE

MECHANICAL MACHINES $99.99

COMPUTERIZED MACHINES $149.99

SINGLE NEEDLE EMBROIDERY MACHINES $179.99

MULTI-NEEDLE EMBROIDERY MACHINES $279.99

LONG ARM MACHINES $249.99

SERGER/OVERLOCK MACHINES $149.99

FRONT OF HOUSE DIAGNOSTIC FREE

BENCH DIAGNOSTIC $45

Have you heard?! For optimum sewing efficiency, your sewing machine needs to be serviced by skilled specialists every 12 to 18 months. Internal oil and lubrication dries out in time. This can be from excess dust and particles inside your machine absorbing the oil, and our dry Boulder Colorado environment generally drying the inner mechanics of your machine. Without correct lubrication inside your sewing machine, the parts that move inside will no longer move! When these parts do stick, lots of problems can happen triggering considerable repair costs to your precious sewing machine. A stuck hand wheel can be the result of old oil that has actually dried out and could fractured interior parts. If you need your sewing machine to run in excellent form and keep producing stunning projects, bring your machine to our Vacuums R Us & Sewing Too – Boulder Store for a tune-up every 12 to 18 months!

We strive to be your first choice for sewing machine and vacuum service in Boulder Colorado! We fix and service all brand names and types of sewing machines from straight stitch to embroidery to sergers and cover stitches. We are an authorized service center for Singer, Janome, Viking Husqvarna, Elna and Elnitta. We also service Bernina, Pfaff, Juki, Baby Lock, Necchi, Brother, Kenmore, Bernette Dress Maker, and more.

If your sewing machine needs more than a standard servicing or tune-up, our trained technicians give complimentary quotes on repair costs prior to authorizing repair. Our front of shop reps will completely check out your sewing machine with you during the check in process. Our experts in Boulder will check if your hand wheel turns, check for zig zag and other stich functionality, tension and timing. We ask you to take home any type of extra accessories you might have brought with your machine, including sewing machine handbooks, optional presser feet, accessory trays, spindles of thread. Our techs will just require the common presser foot, foot control, power cable, bobbin holder as well as bobbin to finish your sewing machine tune-up or repair.

Once your machine gets on our technicians benches in Boulder they will check if your sewing machine powers on and look for any kind of burrs or problems to the needle plate, hook and bobbin. Burrs can create thread damage when sewing, odd uneven stitches and tension problems.

We then evaluate thread distribution on your sewing machine to make sure there is no damages to the stress discs and examine spring tension retention on the machine. Stress is evaluated on your top thread to make sure there is tension after being fed through the sewing machine.

Many integrated needle threaders on a sewing machine have a little cord that draws the thread via the eye of the needle. This small little cord can flex in time or if the integrated needle threader is being utilized with some decorative thread, or smaller sized sewing machine needles. If your sewing machine has an integrated needle threader, our technicians evaluate the needle threader as well as make any type of modifications are adjustments. If your sewing machine’s needle threader cable is badly worn or missing and adjustments can not be made, swapping out the needle threader hook might be suggested.

The bobbin winder on your sewing machine is evaluated for performance, checking for appropriate stress and speed. The bobbin spun by our technicians is placed right into the bobbin case, where the technicians examine your sewing machine’s bobbin tension. If there are any kind of variations to correct bobbin tension, our technicians will make the essential modification and restore correct tension.

Sewing machines feed product with the machine with the assistance of 2 lengthy teeth extending out from your needle plate location. When your sewing makers feed teeth, or feed canines, do stagnate product with your sewing machine correctly or equally, there might be various other repair work required. Your sewing makers feed system is evaluated by our specialists to make certain the feed pets are moving on throughout basic sewing and also in reverse throughout opposite. If your sewing machine has the alternative to elevate as well as reduce the feed teeth, this system is additionally examined. Many contemporary sewing devices have the option to elevate and reduce your sewing feed pet dogs for darning or free movement quilting.

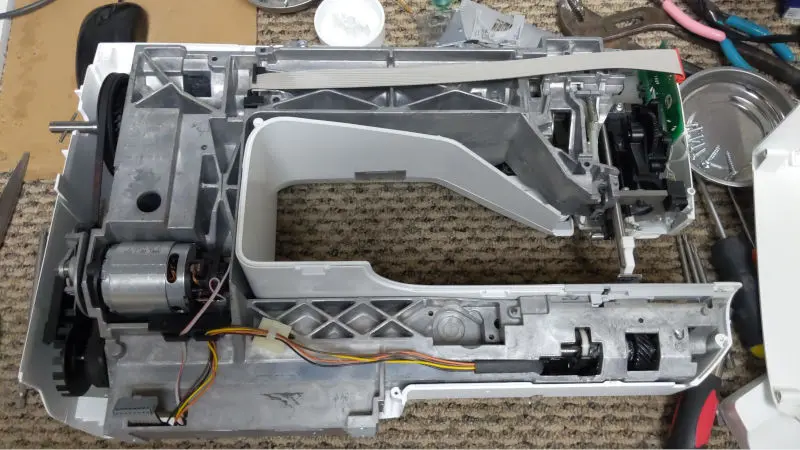

As soon as all outside parts are checked and tested by our certified service technicians, your sewing machine’s outside cover is taken off to start the interior service of your machine. With the covers removed, the techs clean the inner chassis by getting rid of all dirt, dust, and particles. Any type of old oil and grease is eliminated from your sewing machine equipment’s and discs. After the sewing machine has been cleaned inside, our we use brand-new oil to the parts needing and grease parts which require grease instead of oil.

Sewing devices need appropriate timing to develop perfect stitches. If the eye of your sewing machine needle does not go into the bobbin location at the perfect time, your sewing machine will not create a stitch appropriately. Sewing machines create stitches by knotting both the leading thread as well as bobbin thread with each other, the outcome is the sewing machine needle knotting with the bobbin thread at the perfect time. After your sewing machine has been cleaned as and lubricated, our technician will install a brand-new needle right into your sewing machine, inspect your machine’s feed timing and retime your hook to make sure perfect sewing on the machine. Our service technicians will certainly adjust sewing machine’s needle bar elevation. Any type of difference in manufacture needle bar elevation can change your sewing machines sewing, leading to skipped stitches, ticking sounds and not having the ability to draw your bobbin thread up continually.

If your sewing machine is electronic, our experts will inspect your sewing devices firmware. Many sewing machine producers launch brand-new updates to your electronic sewing machine regularly. Our repair specialists will install the most recent updates to your electronic sewing machine so you are up to date!

The last procedure of our sewing machine solution consists of an outside cleaning of your sewing machine. Our techs clean the outside of you sewing machine with a 100% natural cleaner, without damaging chemicals.

Finally, our technicians complete a comprehensive and final test of your sewing machine. Your sewing machine is tested over one minute at its fastest sewing rate. This guarantees your sewing machine runs efficiently and assists in feeding the oil through the machine. Our certified professionals will then test numerous stitch examples on your sewing machine.

- Straight stitch to check your sewing machine sews at top quality

- Reverse sewing to examine the reverse system of your sewing machine

- Zig-zag sew to check your machine’s needle bar device

- Three-way zig-zag stitch or a healing stitch to check your sewing machines needle placements

- Ornamental stitch to examine total capability of sewing machine

At Vacuums R & Sewing Too – Boulder Store, our experienced professionals offer top quality sewing machine solutions and also notions, as well as high quality repair services. Bring your machine in to the specialists that understand the importance of your sewing machine!