Industrial Sewing Machine Repair in Colorado

Industrial sewing machine repair and service is necessary so your machine works at its best to produce the masterpiece you have in mind. Any hitch in the machine and you end up with a product you hope the world never sees. So, it is in the best interest of everyone to have their sewing machines working smoothly and efficiently. However, just like everything in life, sewing machines run into problems during their lifespan. This is more so in commercial sewing machines, which are used more frequently. But you need not worry because an experienced set of hands can fix most of these issues.

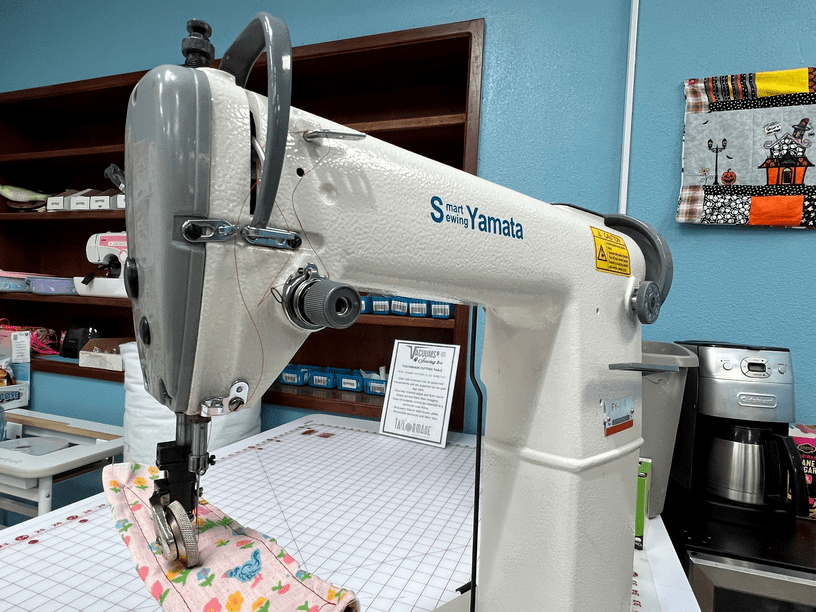

If you are in search of industrial sewing machine repairs in Colorado (Boulder & Arvada), we at “Vacuums R Us & Sewing Too” have a highly qualified team itching to tackle your problems. Trained in fixing the biggest industrial sewing machine brands around (Singer, Elna, Janome, Juki, Kenmore and much more!), our team of specialists will have your machine repaired in no time. Plus, thanks to over 19 years of experience in industrial sewing machine repair and maintenance, we’ve seen all the problems a machine can cause and have yet to run into an issue that we couldn’t handle.

Moreover, we understand the importance of a sewing machine, especially in a commercial setting. Therefore, we also offer service options such as onsite repairs and emergency repairs.

When & Why: Servicing Your Industrial Sewing Machine

A commercial sewing machine is just like any other device which requires regular maintenance to perform at its best. Many people ignore this fact till the machine requires heavy repairs. Sadly, most of these repairs could have been avoided in the first place if the unit was serviced frequently.

So, how often should you service your sewing machine? Sewing machines need to be serviced based on their usage. A sewing machine that’s barely used will require a tune-up about once every 2 years. However, those that are frequently used, such as industrial sewing machines, need to be serviced by a skilled technician every 8 to 12 months. Regular maintenance sessions can bring about certain benefits, such as:

Long Operational Life

A sewing machine is a collection of many moving parts. These parts need to be lubricated in order to reduce wear and tear. However, the oil and grease used for lubrication gradually dry up, increasing friction between components.

Excessive friction can lead to irreversible damage that shortens the life span of the machine. Luckily, owners can prevent this from happening by getting their units serviced by certified commercial sewing machine repair centers.

Although replacements seem like a suitable solution to this problem, they can be temporary fixes depending on the part manufacturer. Most off-brand components are made of low-quality material. Thus, they create trouble affecting the health of the machine. That’s why we advise our customers to employ repair centers that deal with brand-recognized parts.

Cost Savings

As mentioned above, a well-maintained industrial sewing machine will have less wear and tear. Therefore, the parts of these units rarely require replacements. This can save you a ton of money in the long run.

Further, any repair sessions you might have in the future will be quite cheap as well. This is because it takes way more effort to figure out any issues that an unserviced sewing machine might have compared to a regularly maintained unit.

We ourselves have repaired units that demanded more time and energy just because they weren’t regularly maintained.

Quality Results

An industrial sewing machine is a collection of many mechanisms. An issue with any of these functions will affect the performance of the unit. Frequent tune-ups will ensure that these mechanisms work under optimum conditions. Thus, you can expect the machine to produce those elegant stitches, every tailor desires.

What Goes into an Industrial Sewing Machine Repair?

We at “Vacuums R Us and Sewing Too” take a meticulous approach when repairing commercial sewing machines. We strongly believe that no part should be overlooked during the repair and maintenance process. Thus, our technicians have come up with an effective time-tested strategy for industrial sewing machine repair, which has resulted in many happy customers. Let us have a quick look at the different steps this approach comprises.

Initial Testing

Our commercial sewing machine repair process starts with an initial test run, which helps us determine the faults the machine might have.

During the inspection, we employ the machine to create different stitches and keep an eye out for any abnormal behavior. We also record different parameters, such as the bobbin speed and thread tension. The recorded data helps us determine if the machine performs according to the benchmark set by the brand. Further, the data helps us determine if the repair and tune-up process has been a success in the end.

External Checkup

Once our technicians are done with the initial test run, they move on to inspecting the exterior of the machine. They do this to ensure that there has been no damage to the visible exterior, which might affect the performance of the unit.

They also make sure that the machine has all the required parts to perform optimally and that nothing is amiss. Any parts that are missing or damaged are recorded at this stage.

Further, our experts keep an eye out for burrs along the body as well. Burrs can affect the tension in the thread distribution and can also damage the thread during operation.

Power Flow Assessment

Power-related issues are quite common in an industrial sewing machine. Thus, they need to be fixed ASAP, as they might lead to short circuits and scrambled circuits if left untreated.

During the power flow assessment, we check if the machine has a smooth start and if the motor stalls during operation. Further, the panel lights and other displays are checked for flickering, which might indicate an issue with the power supply. We also make sure that the machine draws its rated power during operation.

Checking the Thread Distribution

The top and bottom threads of a sewing machine need to work in harmony to create quality stitches. However, the different mechanisms that help produce them deteriorate gradually. Thus, it is important to evaluate the thread distribution within the unit.

When inspecting the thread distribution, our specialists ensure that the stress discs and the spring tension retention of the machine work as intended. They also test the different parts the threads go through during operation. As these parts can vary depending on the brand, our techs employ different methods to examine them.

Aside from the stress survey, we keep an eye out for bent cables and clogged valves that might obstruct the sewing process as well. All issues we come across are fixed immediately and any replacements needed are run by our customers. Most modern industrial sewing machines come with in-built needle threaders that help draw the thread through the eye of the needle using a little cord. These cords often get damaged because of excessive use. Our experts will evaluate the condition of the needle threader and make any repairs required. They might also suggest a needle bar replacement if there is considerable damage to the mechanism.

Examining the Bobbin Winder

Inspecting the bobbin winder is an important step in any commercial sewing machine repair process. The bobbin winder loads thread from a large spool to a small spool that sits in the bobbin compartment of the unit. Any issue with this mechanism can lead to uneven and tangled windings, which affect the sewing experience.

Our experts make sure that the thread is fed smoothly into the bobbin. They inspect the bobbin tension and make the necessary corrections to have it run under optimum conditions.

Further, they perform a stress check to ensure that the thread is under the right tension. Too tight and the thread might break, too loose and the thread might unravel. Finding that sweet spot in between is what our techs strive for.

Feed Dogs and Fabric

Once we’ve corrected any issues with the unit’s thread distribution, we inspect the machine’s fabric feed mechanism.

Many industrial sewing machines employ a moving pair of metal teeth commonly referred to as feed dogs to handle the fabric. The movement of the feed dogs depends on the brand of the machine in question. Most have the ability to move back and forth, while some are capable of elevation and even changing the number of teeth in use. Regardless, a smooth-functioning feeding mechanism is crucial in creating flawless stitches. Thus, we make sure that every part involved in the fabric feeding process works as intended.

Interior Oil and Timing

When our certified specialists are done inspecting the exterior of the unit, they examine the machine’s interior workings. They first take off the covers and then examine the inner condition of the unit.

This is the stage of the industrial sewing machine repair process we dread the most. Mainly because over the years in service we’ve come across countless machines with beautiful exteriors only to showcase awful interiors due to irregular tune-ups. Frankly, we were surprised that some of them even operated, given their condition.

After assessing the internal state of the unit, our techs clean the interior chassis. They employ various tools to ensure that every bit of dust, dirt and other unwanted particles are removed. Old oil and grease used in various mechanical entities, such as discs, are also eliminated at this stage. When the interior is thoroughly cleaned, we use brand-new oil to lubricate the moving parts to guarantee smooth functionality.

Once we are satisfied with the interior clean-up, we move on to troubleshooting issues related to the timing of the unit, which is an important step in any commercial sewing machine repair strategy.

Sewing devices create stitches by knotting the lead thread and the bobbin thread together. The “bobbin thread” is usually run underneath the fabric while the “lead thread” carrying needle punctures the material from above. When the needle reaches a certain distance after piercing the fabric, a shuttle hook connected to the bobbin driver grabs hold of the lead thread. The shuttle hook then spins around, creating a stitch.

If the shuttle hook does not reach the needle in time, no stitch would be made, and you’d just be left with punctured fabric. So, our techs re-time the hook and inspect the complete bobbin mechanism to make sure that it works flawlessly. If they feel like the parts have run their course, they might also suggest replacing them.

Final Performance Review

The last step of our in-house industrial sewing machine repair strategy is a performance review. At this stage, the unit undergoes various tests designed to analyze different performance criteria.

We usually start the review by running the machine at its fastest sewing speed for over one minute. This helps us to determine any unidentified defects in the motor and also helps feed the newly applied oil throughout the machine. Next, we use the machine to create different stitches (straight, zig-zag, ornamental and many more) using different threads at varying speeds. We complete the review by carrying out a few more tests to determine other parameters such as thread tension. Finally, if the unit meets our expectations, we call you to say that your machine is fixed and ready to create more masterpieces.

Industrial / Commercial Sewing Machine Repair in Arvada

Although this is far from being a complete guide, we trust that you understand how we at “Vacuums R Us & Sewing Too” carry out our commercial sewing machine repairs. We’ve dedicated over 19 years to the craft and have created many happy customers along the way. Thus, you can rest assured that your machine is in good hands if you select us to carry out your industrial sewing machine repairs.