How to Replace a Pump in a Rug Doctor Carpet Cleaner

Replacing Your Rug Doctor Pump - Step by Step Guide

The machine in question is a Rug Doctor that is not spraying water. There are two common issues that could be causing this: a blocked metal screen in the water reservoir, or a failed pump. The metal screen can become clogged with animal hair, preventing water from reaching the pump. The pump can also fail, which is the most common reason for the machine not spraying. If the pump is the issue, it can be replaced, though there are some electrical issues in the handle that can also cause the machine not to spray. However, these issues are rare. To replace the pump, the plastic shroud and bottom plastic shroud should be removed, along with the screws. The pump is located under these parts and can be removed and replaced, using the instructions provided in the shipping box. If the hose clamps are difficult to remove, the hose can be cut and attached to the new pump. It is recommended to not constantly cut the hose as it may run out over time. The pump should then be reattached and tested.

To replace a Rug Doctor pump, you will need to first gather the necessary tools and materials. You will need a replacement pump, a flathead screwdriver, pliers, and a new hose clamp or electrical tape. Then, follow these steps:

- Turn the Rug Doctor upside down and remove the bottom plastic shroud by removing the screws.

- Locate the pump, which is located near the bottom of the machine.

- Disconnect the water pipes and the electrical connections from the old pump.

- Remove the old pump by loosening the hose clamp or cutting the hose if the clamp is stuck.

- Install the new pump by attaching the water pipes and electrical connections. Use a new hose clamp or wrap the connection in electrical tape to secure it.

- Replace the bottom plastic shroud and screws.

- Turn the Rug Doctor right side up and test the new pump to ensure it is functioning properly.

Note: If you are not comfortable performing this repair, it is recommended to seek the assistance of a professional.

Rug Doctor Pump Replacement Video

Finding the Correct Rug Doctor Pump

There are several part numbers that are associated with Rug Doctor pumps, including p4xxa, 12158, and 12139. These pumps are said to vary in wattage and pressure, but it is unclear if there is a noticeable difference in spray volume or velocity between the 50 and 60 watt pumps. Therefore, it may not be necessary to pay attention to the specific part number when replacing the pump.

These are the pumps that we currently stock for this repair:

More Information

There are a lot of things that can go wrong outside the pump or in tandem with a pump failure. In order of frequency:

- There is a metal screen filter inside the clean water tank over the intake hose. That commonly gets clogged so check that. It also some times comes dislodged from the base of the tank and will be sticking out the top of the water which obviously prevents it from getting fluid.

- Hoses get kinked. This is particularly commons where the hose goes up in to the upper motor housing on some models.

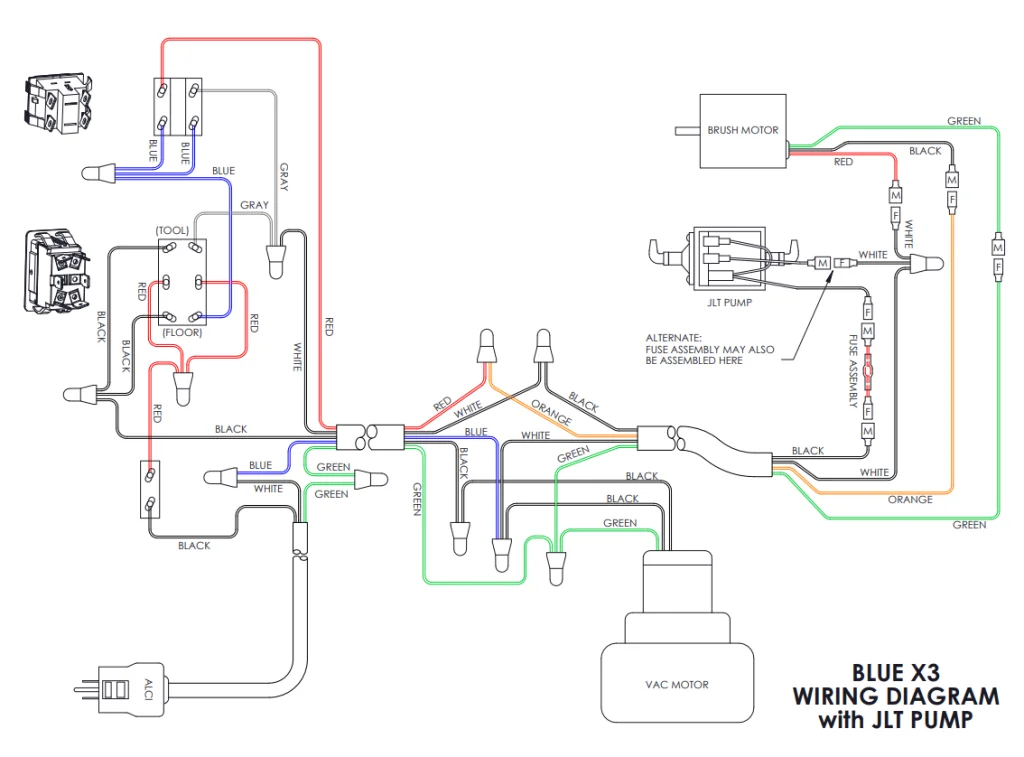

- Use a multimeter to check continuity from the plug all the way to the pump. Generally if there is a continuity issue the brush motor also does not fire and it is an issue with the switch in the handle. I have seen however where the brush motor does fire but the lead that goes from the wire loom to the pump is corroded and does not have continuity.

- The spray tips can clog but this is incredibly rare. These are pretty high pressure pumps and they pretty much blast anything out of the system. However, if a highly concentrated detergent is used it can create sediment build up in the tips.

- A defective new pump is obviously possible. We’ve installed over a thousand and never had one bad out of box. Of the hundreds of “defective” pump returns we’ve taken not one was actually defective except for the cases where the customer returned their obviously previous defective pump and kept the new one (which is why we no longer sell on Amazon, their customer base seems to be more prone to scumbaggery). You can test the pump by simply putting it in a vice to hold it and plugging a hose in to the intake in to a water cup and hot wiring it. This however is not a thing I suggest you try unless you are an authorized service center.

Unfortunately, all of these issues with the exception of the screen are a pain to track down. 98% of no spray failures are just bad pumps so most people have success simply replacing a pump. There is that one out of 50 though that gets hairy.

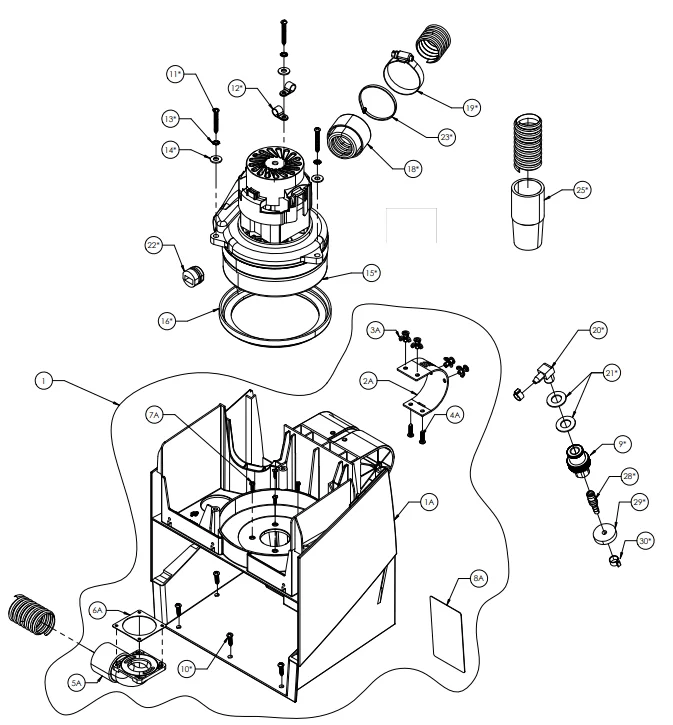

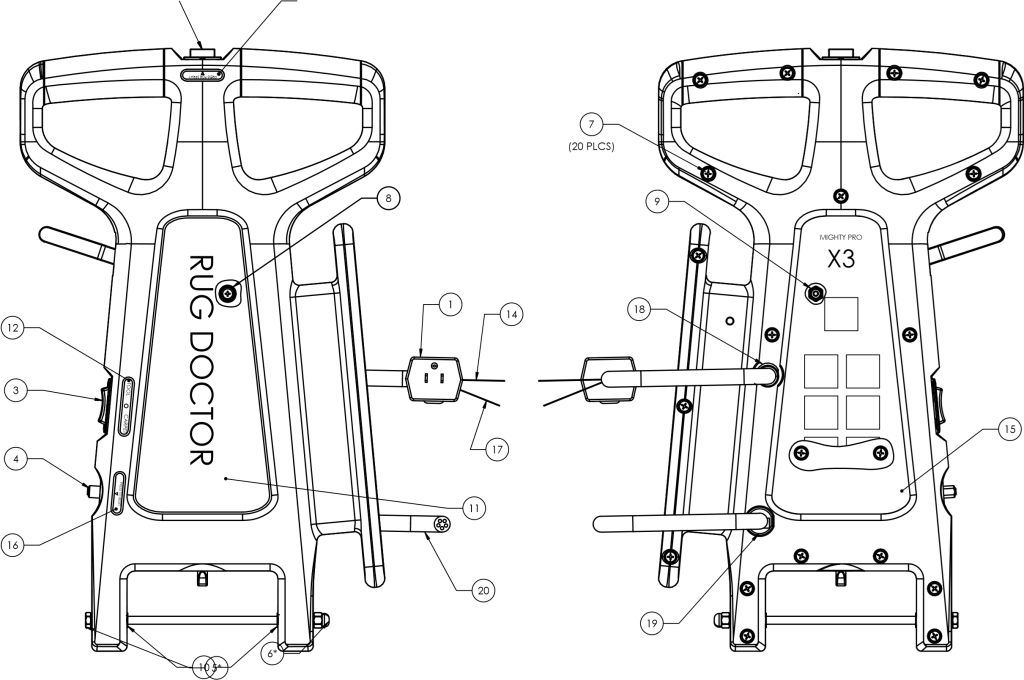

Full Rug Doctor Schematic

Download the full PDF schematic here

Full wiring diagram rug doctor blue X3

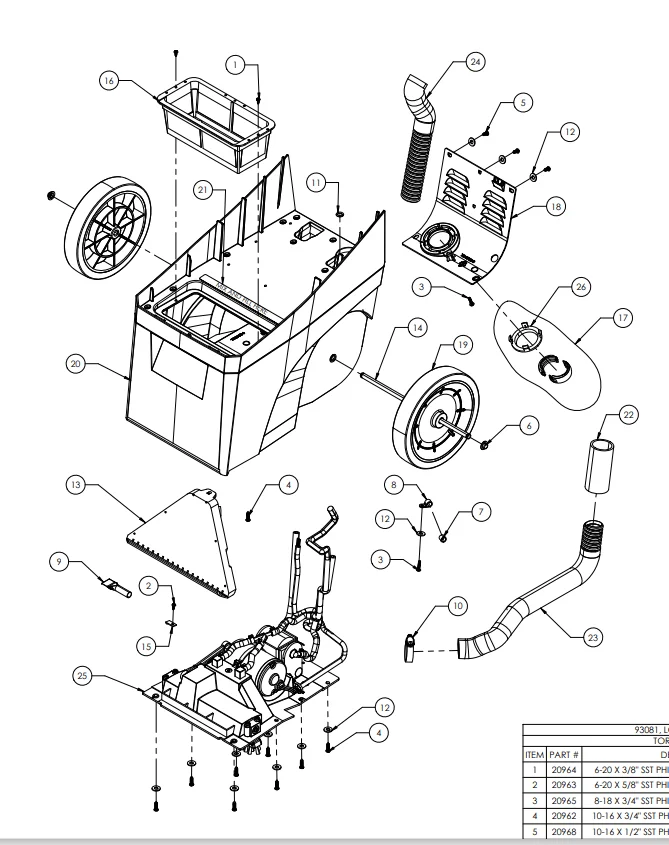

| 93081, LOWER TANK ASSY | |||||||||||||||||||||||||||||||||||||

| AVAILABLE REPLACEMENT PARTS | |||||||||||||||||||||||||||||||||||||

| ITEM | PART # | DESCRIPTION | QTY | ||||||||||||||||||||||||||||||||||

| 1 | 20964 | 6-20 X 3/8″ SST PHILLIPS BUTTON HEAD SCREW | 2 | ||||||||||||||||||||||||||||||||||

| 2 | 20963 | 6-20 X 5/8″ SST PHILLIPS BUTTON HEAD SCREW | 1 | ||||||||||||||||||||||||||||||||||

| 3 | 20965 | 8-18 X 3/4″ SST PHILLIPS BUTTON HEAD SCREW | 2 | ||||||||||||||||||||||||||||||||||

| 4 | 20962 | 10-16 X 3/4″ SST PHILLIPS BUTTON HEAD SCREW | 9 | ||||||||||||||||||||||||||||||||||

| 5 | 20968 | 10-16 X 1/2″ SST PHILLIPS BUTTON HEAD SCREW | 3 | ||||||||||||||||||||||||||||||||||

| 6 | 45183 | 3/8″ HUB CAP | 2 | ||||||||||||||||||||||||||||||||||

| 7 | 60798 | GROMMET FOR CABLE SJT | 1 | ||||||||||||||||||||||||||||||||||

| 8 | 60796 | CABLE P CLAMP | 1 | ||||||||||||||||||||||||||||||||||

| 9 | 10461 | LINE STRAINER, SUMP FILTER, 2-1/2″ L | 1 | ||||||||||||||||||||||||||||||||||

| 10 | 11995 | CLAMP HOSE 25-40m m SST, ZINC SCREW | 1 | ||||||||||||||||||||||||||||||||||

| 11 | 60797 | O-RING 9/16″ O.D. | 1 | ||||||||||||||||||||||||||||||||||

| 12 | 20853 | WASHER FL #10 X .518″ O.D. | 12 | ||||||||||||||||||||||||||||||||||

| 13 | 45123 | NOZZLE FLO OR WITH ROLLED LIP | 1 | ||||||||||||||||||||||||||||||||||

| 14 | 45124 | REAR AXEL 3/8″ DIA X 11 1/2″ L | 1 | ||||||||||||||||||||||||||||||||||

| 15 | 60262 | TAB SUMP LINE RETAINER | 1 | ||||||||||||||||||||||||||||||||||

| 16 | 60400 | FILTER SCREEN 9.11″ L | 1 | ||||||||||||||||||||||||||||||||||

| 17 | 93079 | SPLIT GROMMIT KIT | 1 | ||||||||||||||||||||||||||||||||||

| 18 | 60776 | VENT PANEL | 1 | ||||||||||||||||||||||||||||||||||

| 19 | 60778 | WHEEL TIRE 8″ DIA. SMOOTH HUB | 2 | ||||||||||||||||||||||||||||||||||

| 20 | 65414 | BLUE TANK HOUSING COMPLETE W/ BUSHINGS | 1 | ||||||||||||||||||||||||||||||||||

| 21 | 77001 | MIX AND FILL HERE LABEL | 1 | ||||||||||||||||||||||||||||||||||

| 22 | 80773 | HOSE END ENLARGED | 1 | ||||||||||||||||||||||||||||||||||

| 23 | 85246 | VAC HOSE 18″ L (NOZZLE TUBE) | 1 | ||||||||||||||||||||||||||||||||||

| 24 | 85250 | VAC HOSE EXHAUST 22″ L | 1 | ||||||||||||||||||||||||||||||||||

| 25 | 93089 | BOTTOM PAN SUB ASSY | 1 | ||||||||||||||||||||||||||||||||||

| 26 | 60767 | GROMMET RETAINER | 1 | ||||||||||||||||||||||||||||||||||

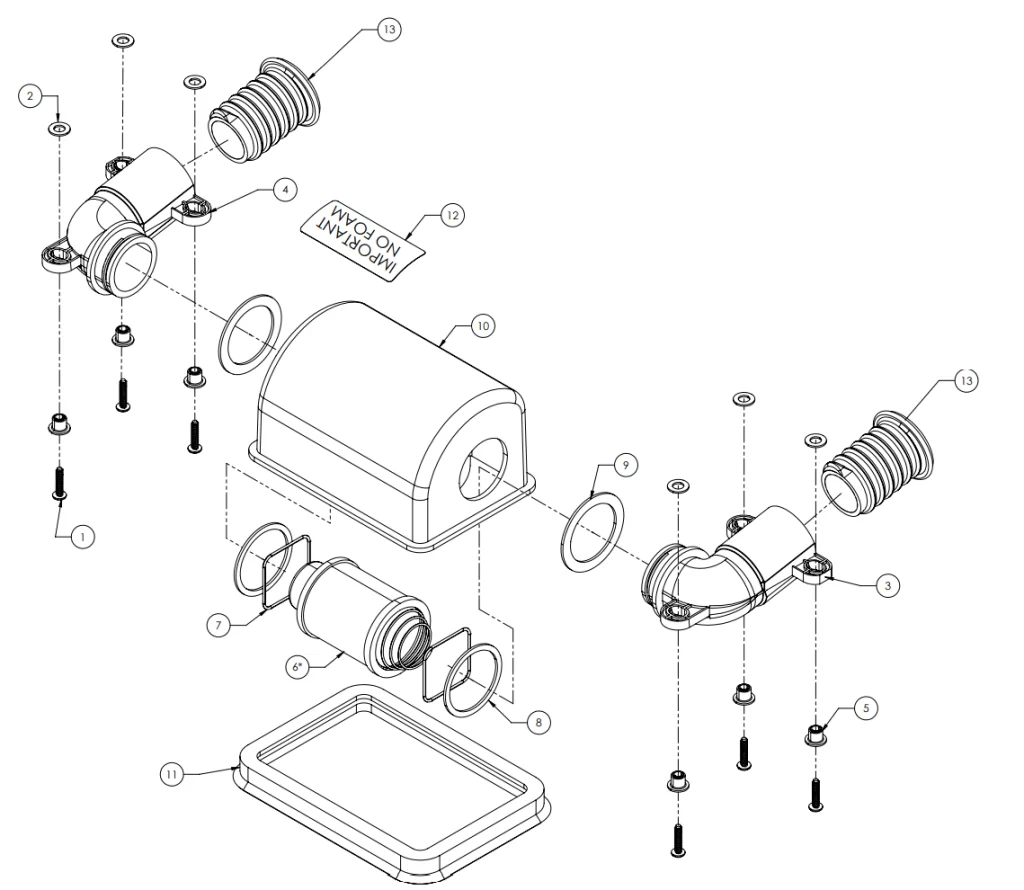

| HOSELESS DOME ASSY | |||||||||

| REPLACEMENT PARTS AVAILABLE: | |||||||||

| ITEM | PART # | DESCRIPTION | QTY | ||||||

| 1 | 20965 | SCREW, 8-18 X 3/4″ SST | 6 | ||||||

| 2 | 20967 | FLAT WASHER, 1/2″ OD | 6 | ||||||

| 3 | 60787 | ELBOW, 90 FLANGE A | 1 | ||||||

| 4 | 60771 | ELBOW, 90 FLANGE B | 1 | ||||||

| 5 | 45185 | BUSHING, DOME ELBOW | 6 | ||||||

| 6* | 10460 | FILTER SCREEN WITH SPRING | 1 | ||||||

| 7 | 41183 | CLIP, RETAINER | 2 | ||||||

| 8 | 60196 | WASHER, PLASTIC, BLACK | 2 | ||||||

| 9 | 60591 | GASKET, ELBOW 2″ OD | 2 | ||||||

| 10 | 60769 | DOME, CLEAR | 1 | ||||||

| 11 | 60770 | GASKET, DOME | 1 | ||||||

| 12 | 77006 | DECAL, NO FOAM | 1 | ||||||

| 13* | 61082 | DOME HOSE ADAPTOR | 2 | ||||||

| 93082, COMPLETE HANDLE ASSY WITH CORDS AND LABELS | |||||||||||||||||||||

| REPLACEMENT PARTS AVAILABLE: | |||||||||||||||||||||

| ITEM | PART # | DESCRIPTION | QTY | ||||||||||||||||||

| 1 | 91651 | ALCI PLUG & CORD, 28 FT, FOR X3 | 1 | ||||||||||||||||||

| 2 | 51060 | SWITCH, PB, RED | 1 | ||||||||||||||||||

| 3 | 51107 | SWITCH, ROCKER, ON-OFF-ON | 1 | ||||||||||||||||||

| 4 | 51129 | CIRCUIT BREAKER, 15 AMP | 1 | ||||||||||||||||||

| 5* | 20386 | BOLT, 1/4-20 X 7-1/2″ | 1 | ||||||||||||||||||

| 6* | 20859 | ACORN NUT 1/4-20 | 1 | ||||||||||||||||||

| 7 | 20962 | SCREW, 10-16 X 3/4″ SST PHILLIPS HEAD | 20 | ||||||||||||||||||

| 8 | 20966 | SCREW, 8-32 X 7/8″ SST SLOT BUTTON HEAD | 1 | ||||||||||||||||||

| 9 | 20241 | NUT NYLO CK 8-32 SST | 1 | ||||||||||||||||||

| 10 | 41189 | BUSHING | 2 | ||||||||||||||||||

| 11 | 77011 | LABEL, RD FRONT LOGO | 1 | ||||||||||||||||||

| 12 | 77010 | LABEL, ON-OFF CRPT/UPH | 1 | ||||||||||||||||||

| 13 | 77008 | LABEL, PRESS FOR SPRAY | 1 | ||||||||||||||||||

| 14 | 77007 | LABEL, CAUTION/ GROUND | 1 | ||||||||||||||||||

| 15 | 77003 | LABEL, REAR, CARPET CONN/UPHOLSTERY INSTRUCTIONS | 1 | ||||||||||||||||||

| 16 | 77002 | LABEL, CB RESET | 1 | ||||||||||||||||||

| 17 | 76815 | LABEL, WARNING PROP 65 | REF | ||||||||||||||||||

| 18 | 60795 | GROMMET HEYCO 1232 | 1 | ||||||||||||||||||

| 19 | 60794 | GROMMET HEYCO 1497 | 1 | ||||||||||||||||||

| 20 | 55321 | 5-CONDUCTOR CORD | 1 | ||||||||||||||||||

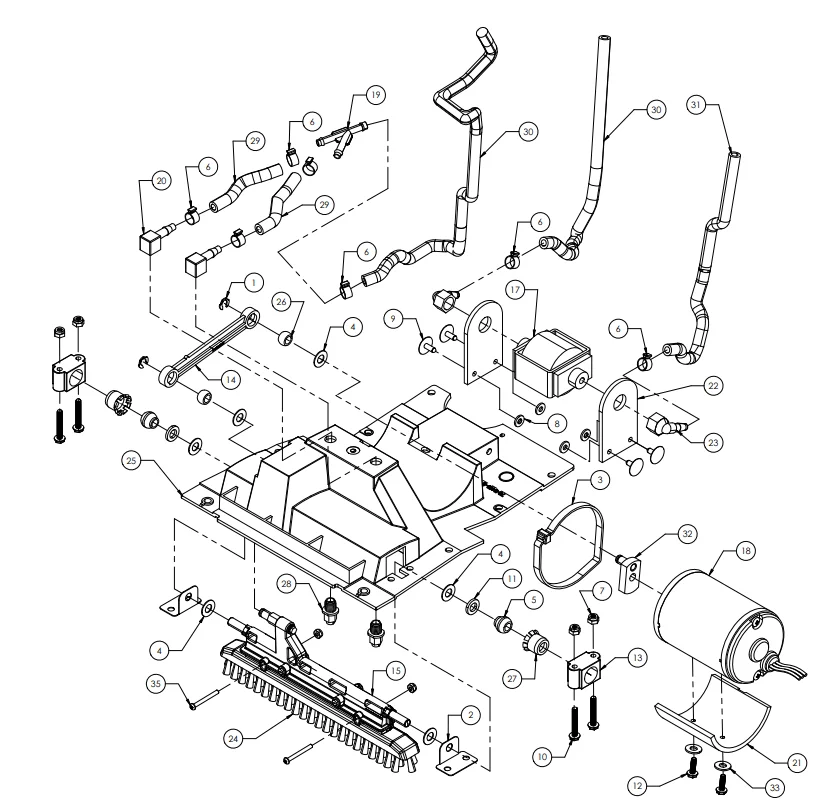

| 93089, BOTTOM PAN ASSY 120V | |||||||||||||||||||||||||||

| AVAILABLE REPLACEMENT PARTS: | |||||||||||||||||||||||||||

| ITEM | PART # | DESCRIPTION | QTY | ||||||||||||||||||||||||

| 1 | 20604 | RETAINING C-CLIP PO-25 | 2 | ||||||||||||||||||||||||

| 2 | 60792 | MYLAR SPLASH GUARD | 2 | ||||||||||||||||||||||||

| 3 | 60166 | BLACK TIE, PASTIC STRAP | 1 | ||||||||||||||||||||||||

| 4 | 10316 | WASHER, NYLON .341″ ID, .68″ OD, .06″ THK | 6 | ||||||||||||||||||||||||

| 5 | 10341 | BEARING PILLOW BLO CK | 2 | ||||||||||||||||||||||||

| 6 | 11845 | CLAMP, HOSE, OETIKER 12m m | 7 | ||||||||||||||||||||||||

| 7 | 20231 | NUT NYLO CK 10-32 SST | 4 | ||||||||||||||||||||||||

| 8 | 20266 | WASHER AL .200″ ID | 4 | ||||||||||||||||||||||||

| 9 | 20388 | RIVET ALUM LARGE HEAD | 4 | ||||||||||||||||||||||||

| 10 | 20390 | SCREW 10-32 X 1-1/4″ FLANGE HEX HEAD | 4 | ||||||||||||||||||||||||

| 11 | 20840 | WASHER, FELT 5/8″ | 2 | ||||||||||||||||||||||||

| 12 | 20906 | SCREW 10-32 X 5/8″ FLANGE HEX HEAD | 2 | ||||||||||||||||||||||||

| 13 | 40353 | PILLOW BLO CK | 2 | ||||||||||||||||||||||||

| 14 | 40388 | DRIVE ARM SELF ALIGNING | 1 | ||||||||||||||||||||||||

| 15 | 45125 | BRUSH HOLDER ASSY AL | 1 | ||||||||||||||||||||||||

| 17 | 12158 | PUMP REPAIR KIT | 1 | ||||||||||||||||||||||||

| 18 | 92979 | BRUSH MOTOR KIT | 1 | ||||||||||||||||||||||||

| 19 | 60138 | CONNECTOR Y | 1 | ||||||||||||||||||||||||

| 20 | 60139 | FITTING, BARB, 90° | 2 | ||||||||||||||||||||||||

| 21 | 60598 | GASKET, MOTOR 3/16″ THK RUBBER, 4″ X 3″ | 1 | ||||||||||||||||||||||||

| 22 | 60720 | PUMP MOUNT, 3/16″ THK RUBBER | 2 | ||||||||||||||||||||||||

| 24 | 60779 | BRUSH STRIP ASSY | 1 | ||||||||||||||||||||||||

| 25 | 65415 | BOTTOM PAN | 1 | ||||||||||||||||||||||||

| 26 | 80596 | BUSHING DRIVE ARM | 2 | ||||||||||||||||||||||||

| 27 | 80597 | SLEEVE HOLDER BEARING | 2 | ||||||||||||||||||||||||

| 28 | 80819 | SPRAY JET TIP 110° NYLON | 2 | ||||||||||||||||||||||||

| 29 | 85231 | SOL. HOSE REINF. 1/4″ X 3″ L | 2 | ||||||||||||||||||||||||

| 30 | 85253 | SOL. HOSE REINF. 1/4″ X 18-1/2″ L | 2 | ||||||||||||||||||||||||

| 31 | 85254 | SOL. HOSE REINF. 1/4″ X 35-1/4″ L | 1 | ||||||||||||||||||||||||

| 32 | 90069 | CAM ASSEMBLY | REF | ||||||||||||||||||||||||

| 33 | 20853 | WASHER FL #10 X .518″ O.D. | 2 | ||||||||||||||||||||||||

| 34 | 55320 | CORD,18/4, INTERNAL, 37″, GRAY (NOT SHOWN) | 1 | ||||||||||||||||||||||||

| 35 | 92652 | KIT,BRUSH 6-32 SCREW/LOCK NUT SST (2 EACH) | 1 | ||||||||||||||||||||||||

| 93088, MAIN SUPPORT ASSY WITH GASKET, STRIKER PLATE AND ELBOW | |||||||||||||||||||||||||||||||

| AVAILABLE REPLACEMENT PARTS: | |||||||||||||||||||||||||||||||

| ITEM | PART # | DESCRIPTION | QTY | ||||||||||||||||||||||||||||

| 1 | 93088 | MAIN SUPPORT ASSY, BLUE X3 | 1 | ||||||||||||||||||||||||||||

| 1A | 65413 | MAIN SUPPORT, BLUE | 1 | ||||||||||||||||||||||||||||

| 2A | 40215 | STRIKER PLATE, 3-SLOT | 1 | ||||||||||||||||||||||||||||

| 3A | 20983 | RIVET, AL, 3/16″ DIA,.188-.250GR | 4 | ||||||||||||||||||||||||||||

| 4A | 20962 | SCREW, 10-16 X 3/4, SST | 2 | ||||||||||||||||||||||||||||

| 5A | 60661 | ELBOW, VAC MTR | 1 | ||||||||||||||||||||||||||||

| 6A | 60263 | GASKET, ELBOW | 1 | ||||||||||||||||||||||||||||

| 7A | 20348 | SCREW, 6-20 X 1/2, SST | 4 | ||||||||||||||||||||||||||||

| 8A | 77012 | ETL LABEL | 1 | ||||||||||||||||||||||||||||

| 9* | 80208 | QUICK CPLR BRASS | 1 | ||||||||||||||||||||||||||||

| ORDER 93078 FOR KIT WITH ITEMS 28,29, & 30 | |||||||||||||||||||||||||||||||

| 10* | 20962 | SCREW, 10-16 X 3/4″ SST | 7 | ||||||||||||||||||||||||||||

| 11* | 20961 | SCREW, 10-16 X 1-1/2″ SST | 3 | ||||||||||||||||||||||||||||

| 12* | 60796 | CABLE CLAMP, P-CLIP | 2 | ||||||||||||||||||||||||||||

| 13* | 19466 | WASHER, LOCK #10 EXT | 3 | ||||||||||||||||||||||||||||

| 14* | 20853 | WASHER, FLAT #10 | 3 | ||||||||||||||||||||||||||||

| 15* | 50276 | MOTOR, VAC 120V LINIX | 1 | ||||||||||||||||||||||||||||

| 16* | 65355 | GASKET, VAC MOTOR | 1 | ||||||||||||||||||||||||||||

| 18* | 60726 | COUPLING, THREADED | 1 | ||||||||||||||||||||||||||||

| 19* | 11996 | CLAMP, HOSE 35-55m m | 1 | ||||||||||||||||||||||||||||

| 20* | 80775 | ELBOW, BRASS, 1/4″ | 1 | ||||||||||||||||||||||||||||

| 21* | 20907 | WASHER, .562″ ID | 2 | ||||||||||||||||||||||||||||

| 22* | 60794 | BUSHING, S/R | 1 | ||||||||||||||||||||||||||||

| 25* | 80780 | HOSE END, TAPERED | 1 | ||||||||||||||||||||||||||||

| 28* | 80784 | QUICK COUPLER NIPPLE | 1 | ||||||||||||||||||||||||||||

| 29* | 60725 | WASHER,RUBBER,1-1/4″OD | 1 | ||||||||||||||||||||||||||||

| 30* | 11845 | CLAMP,HOSE,OETIKER | 1 | ||||||||||||||||||||||||||||